For marine applicati ons, engineers have long been aware of the

limitations in corrosion resistance of Aluminium Bronzes and

steels, especially for applications requiring extreme

performance over an extended life time.

Typically this issue has been managed by a twin approach of:

1. Designing thicker sectionsto allow for corrosion

2. Replacing components at intervals throughout the life time

Clearly both options are sub-optimal as they do not address the root cause of

the problem. To address this, the Ministry of Defence commissioned trials to

try to forge a copper-nickel-chrome alloy [DEF STAN 02 824], which had

only previously been produced in a cast and very limited closed die forged

condition.

Compared to aluminium bronze, copper-nickel-chrome is in general ten

times more corrosion resistant and is five times more resistant to shock,

with comparable cost (see overleaf ).

In the early 1990s, extensive funding was given to forging companies to

make a batch of wrought copper-nickel-chrome. The trials were a disaster,

with billets breaking up on forging. Despite the support, the companies at

the time failed and gave up. As a result the Ministry of Defence abandoned

the project.

You achieved what I thought was impossible

Senior Metallurgist, Ministry of Defence

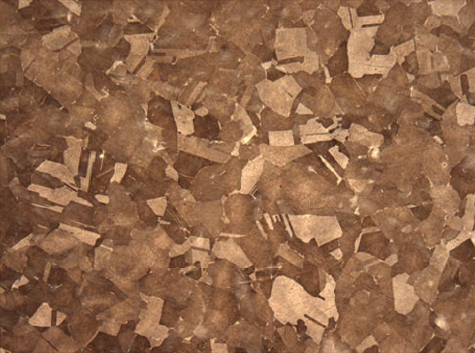

Wrought CNC structure etched 100x magnification grain size around 45μm.png

Wrought CNC structure etched 100x magnification grain size around 45μm.png

United Kingdom

United Kingdom