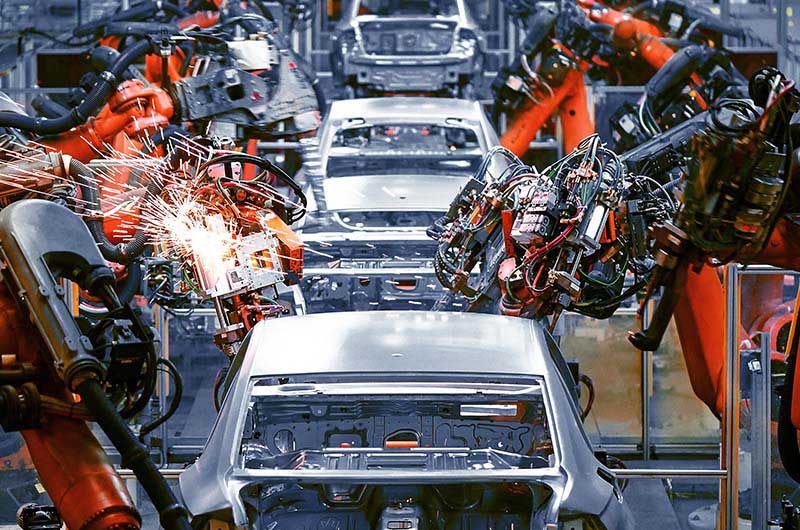

Quite simply, we specialise in the difficult.

Once the drawings for a component have been completed, we support equipment producers and end users in the production of specialist marine defence materials and customised designs.

Normally the geometry is considered at the material selection stage and in addition to manufacturing the metal, we also machine to print, as well as project manage whole sets of components and down-stream activities.

Our engineers have gained extensive experience in the conversion of raw material into finished components, with a full range of machining capability and a deep understanding of the total quality management required to service the industry at the highest level.

Copper Alloys Ltd has an industry leading approach to quality management and, coupled with our unique approach to manufacturing components and forgings from speciality metals.

United Kingdom

United Kingdom