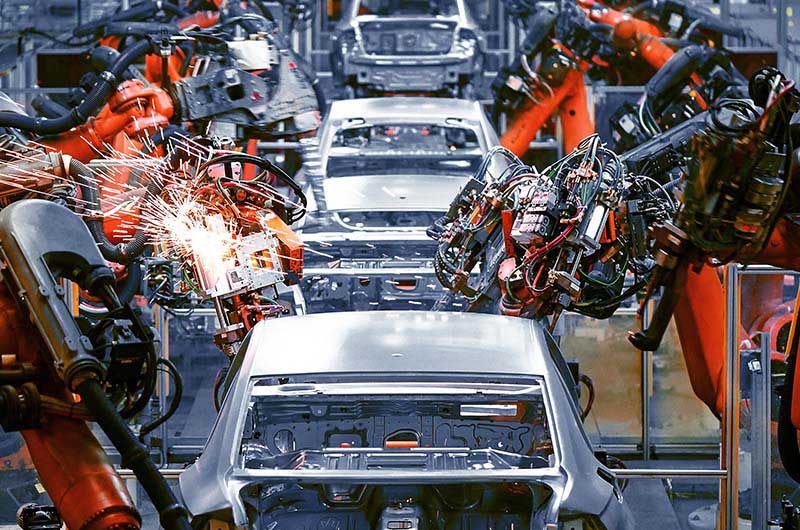

The combination of benefits for engineers working with Copper Alloys Ltd is unique. There are many ways that we can add value to your supply chain:

Over 100 years of combined metallurgical and industrial knowledge within the technical team to help you select the correct material and maximise the mechanical properties for your application.

Eliminating manufacturing risk by allowing Copper Alloys Ltd to conduct the machining on fully machined components.

The key difference is that Copper Alloys Ltd is small enough to care. The entire production and management teams take pride in their work and will go the extra mile to ensure that material or component supply is not the thing that lets you down.

Copper Alloys Ltd are focused on what means most to our customers. Our approach to complete quality management enables us to create and supply material and components that will provide the best value throughout the lifetime of the equipment.

The systems of control at Copper Alloys Ltd guarantee repeatability of process and performance.

United Kingdom

United Kingdom